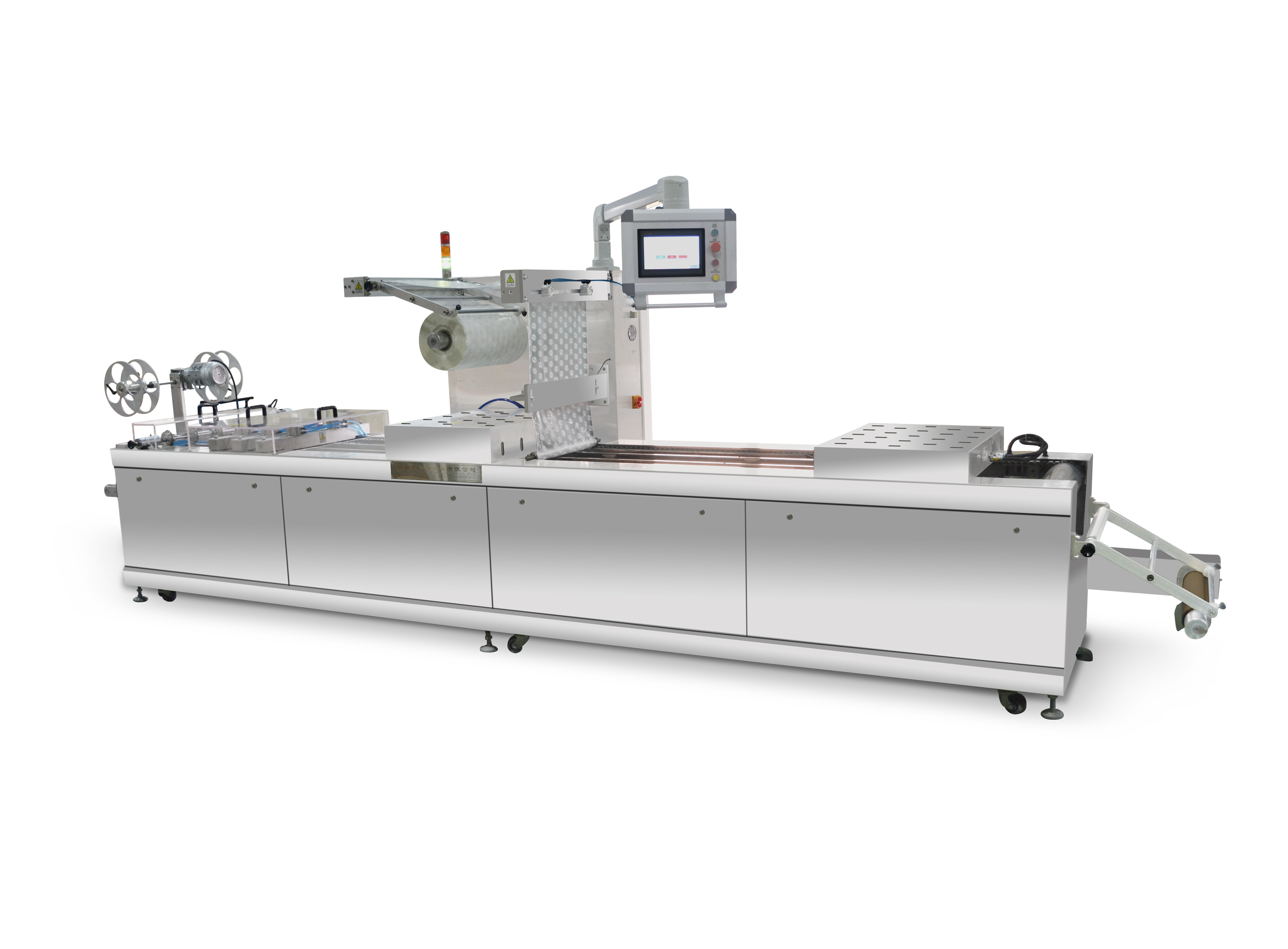

Thermoforming is a manufacturing process in which the product packaging is made on the ground – instead of packing the product. Plastic film and packaging material is heated to forming temperature and a special form (matrix) with the help of air and Vacuums disbanded, obtaining the required form of product packaging. The process of thermoforming packaging is made with equipment that immediately Insertion of a product. Thermoforming machine can add a variety of accessories, such as, for example, with labeller, which straight after the sealing of packages sticks a label on them. Thermoforming technology can be used in small batches for packaging and as a large product line of packaging.

- Easy changing die set

- Durable transport chain which are outstanding corrosion resistance

- Forming and sealing tools are cooled with water

- Sealing temperature and forming temperature are easy to setting by touch screen separately

- Machine with out feed conveyor for easy of product discharge

- Chain advance speed adjustable by touch screen

- Display screen monitor all device status easy to maintenance and service

- Centralized air control system protection for operator

Specification

- Model:HZ-320

- Machine dimension:4450 x 710 x 1800mm

- Width of bottom film:350mm

- Width of sealing film:320mm

- Max. forming depth:80 mm

- Air Supply: 0.8Mpa

- Water consumption: 0.15Mpa

- Power:380V 50HZ

- Model:HZ-420

- Machine dimension:5100 x 810 x 1900mm

- Width of bottom film:450mm

- Width of sealing film:420mm

- Max. forming depth:80 mm

- Air Supply: 0.8Mpa

- Water consumption: 0.15Mpa

- Power:380V 50HZ

- Model:HZ-520

- Machine dimension:7200 x 1000 x 2050mm

- Width of bottom film:550mm

- Width of sealing film:520mm

- Max. forming depth:80 mm

- Air Supply: 0.8Mpa

- Water consumption: 0.15Mpa

- Power:380V 50HZ

options

- Special design is available for various product.

- Coding or labeling.

- Cross cutting applies to different pattern.

- Water cooiing macnine.